Utilization of the complete dentures as a viable tooth replacement option historically dates back over 50 years until present time. Dating back to 700 BC, dentures in Europe and Asia were made of human or animal teeth. In the 1700’s, ivory dentures were popular using natural materials such as walrus, elephant or hippopotamus material. The first U.S. President, George Washington also had infamous dentures. But contrary to popular belief, his dentures were not made of wood but one of the highest quality false teeth of the time. His dentures consisted a denture plate made of carved hippopotamus ivory into which human, horse and donkey teeth were incorporated. In the 20th century, acrylic resin and other plastics became material of choice. Throughout the decades, regardless of the material used, the clinical technique and procedures remained largely unchanged. The fabrication of the complete dentures usually requires a minimum of six to eight appointments to ensure patient acceptance and adaptation for functional chewing.

The modern technology of computer-aided design/computer-aided manufacturing (CAD/CAM) has been well established in dentistry. The fabrication of crown, bridge and implant retained prosthesis with CAD/CAM technology has proven to be less labor intensive while improving quality control of the final prosthesis. The CAD/CAM technology has been extended to the fabrication of complete dentures of the so-called “ Digital Dentures”. The main advantage and difference is the utilization of the three-dimensional computer software to model the dentures using stable anatomical landmarks as reference. The 3D software uses algorithms to combine clonal information with anthropometric data gathered from an average cross section of large patient samples. The digital dentures technique creates an improved accuracy for the intaglio surface of the dentures, hence improving retention and intimate accurate fit to the denture bearing anatomy. All the required information such as incisal edge, lip support, midline, vertical dimension occlusion, centric relation positions and denture occlusion can be formulated by the software to produce a set of “Try-In” dentures. The try in dentures can further be refined, adjusted and altered as required prior to fabrication of the final dentures. The Digital denture process decreases number of appointments and time to insertion of the removable prosthesis. The traditional approach may require between six to eight appointments, while the digital dentures will only require approximately three to four visits.

FIGURE 1. Patient presents with full edentulism for over 20 years and dissatisfied with previous old dentures due to lack of retention, soft tissue support and masticatory function due to worn denture teeth.

FIGURE 2. Retracted view of advance residual ridge resorption pattern and denture bearing compromised anatomy.

FIGURE 3. Four different sizes of initial trays to select to match patient’s existing edentulous ridges or old dentures.

FIGURE 4. Heat applied to alter and shape the plastic tray as required to approximate edentulous ridge anatomy.

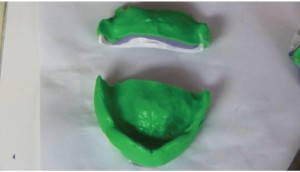

FIGURE 5. Final impression with polyvinyl siloxane light body wash material and border moulding.

FIGURE 6. Sectioning the mandibular final impression in preparation for jaw relations record.

The current market provides several digital denture systems from various manufacturers. The current case demonstration will be using the Pala Digital Denture from Heraeus Kulzer. This system combines final fabrication of final impressions, records jaw relations record and teeth selection into the first appointment. The second appointment will be evaluation of the “Try -In dentures”. The third appointment will be the insertion of the final removable prosthesis. A fourth appointment may or may not be require for post insertion minor adjustments of the intaglio surface or to optimize the denture balanced or lingualized occlusion.

FIGURE 7. Sectioning the maxillary final impression in preparation for jaw relations record.

FIGURE 8. Central bearing device to record centric relations position and gothic tracing for protrusive and excursive pathway movements.

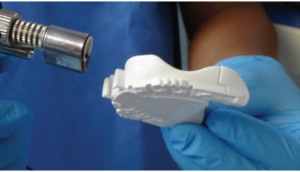

FIGURE 9. Vertical dimension confirmed with adjustable index between trays jaw gauge to patient’s facial proportions to lower third of the face.

FIGURE 10. Jaw gauge from Pala digital dentures to measure facial proportions to determine vertical dimension of occlusion.

FIGURE 11. Centric relations record with bite registration material to record interocclusal positions and vertical dimension of occlusion.

The Pala Digital Denture system comes with four sizes of mouldable trays, scannable polyvinyl siloxane impression material, bite registration material and gothic arch tracing for the centric relations record. A best matching initial tray can be sized to the patient edentulous arch or previous dentures. The trays can be modified with heat or adjustment of tray periphery with lab bur. The polyvinyl siloxane material can be used as the tray material to customize the tray and border moulding followed by a light body wash material to capture accuracy of the anatomical structures. The system can be utilized to fabricate a single denture or full arch dentures. Centric relations record can be recorded with excursive pathways using the Gothic tracing paper attached to the trays. Vertical dimension of occlusion, lip length can be recorded to patient’s anatomical facial positions. Denture teeth shade, mould of teeth, pink acrylic shade and clinical documentation checklist data will be forwarded to Heraeus Pala centre. At the processing centre, all the data will be used to develop the denture design from a stereolithographic prototype printing.

FIGURE 12. Pink acrylic shade selection to match the patient’s existing soft tissue edentulous ridges.

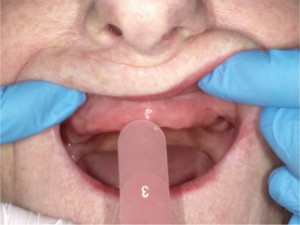

FIGURE 13. Lip ruler to measure patient’s maxillary lip length to aid in selection of maxillary denture teeth length and incisal edge positions.

FIGURE 14. Try in dentures to evaluate fit, retention, stability, support, contour, lip support, aesthetics and vertical dimension of occlusion.

FIGURE 15. Try in dentures to evaluate fit, retention, stability, support, contour, lip support, aesthetics and vertical dimension of occlusion.

FIGURE 16. Mandibular try in denture to refine denture balanced occlusion.

The introduction of digital dentures can improve the quality of the removable complete dentures while decreasing the number of appointments required. This process can overcome many of the traditional contemporary challenges in denture fabrication protocol. The accuracy of the CAD/CAM technology and proprietary processing techniques eliminates polymerization shrinkage and inaccuracies with the intaglio surfaces of the dentures and subsequent denture occlusion.

FIGURE 17. Initial insertion of maxillary and mandibular complete dentures by third appointment.

FIGURE 18. Initial insertion of maxillary and mandibular complete dentures by third appointment.

FIGURE 19. Satisfied patient with digital dentures providing retention, stability, support, aesthetics and functional occlusion.

The case shown demonstrates a step-by-step protocol for the fabrication of the digital dentures.OH

Dr. Mark H. E. Lin graduated from the University of Detroit Mercy for his dental program. He then completed a one-year General Practice Residency program at the Miami Valley Hospital in Dayton, Ohio. He practiced general dentistry for 13 years then returned to compete his postgraduate training in the specialty of prosthodontics at the University of Toronto. He maintains a full-time specialty practice as a prosthodontist at Dr. Mark Lin Prosthodontic Centre.

Oral Health welcomes this original article.