It became painfully obvious to those of us practicing in the 1980s that those new-fangled “posterior” composites were just never going to handle like amalgam. For starters, composites cannot be “condensed” or “packed.”

Ever since then, clinicians, academics, and manufacturers have sought to create or re-design the successful armamentarium for direct esthetic posterior restorations. Most of the original parameters have changed: bonding agent chemistry has evolved through numerous generations; composite particle shapes and size ranges have developed through numerous concepts. In fact, the very composition and fill ratios of our restoratives have been reshaped by research and development. Few of us are still using the same styles of matrix bands, retainers, or wedges. Separate-step etchants have matured, and largely disappeared. Our current curing lights are far more powerful and predictable.

We now have bio-active, antimicrobial, and low-shrinkage composites to choose from, and most practices are utilizing one of the “bulk-fill” composites, saving time and steps, and expediting the placement sequence by reducing layers and interfaces. It is simple math; these innovative ideas make us better dentists, and more profitable, 2-3 minutes at a time. In the post-COVID era, with all the new regulations and restraints that dentists are subject to (including the additional overhead of PPE), clinical efficiency (time, steps, and materials) is more important than ever.

If we revisit the primary dental anatomy texts, such as Linek (https://www.scribd.com/document/338897407/Tooth-Carving-Manual-Henry-A-Linek) that many of us used to “empirically” learn coronal hard tissue anatomy, we find several important axioms:

- The occlusal anatomic features of posterior teeth show little variance from one patient to the next

- The cuspal inclines of the posterior teeth are a fairly standard 97o in angulation

Surprisingly, many clinicians still spend half of their Class II restoration operative chairtime in the shaping, finishing, and polishing of the occlusal surface. Many of us have managed to cobble together our own “Frankenstein” shaping kits, borrowing instruments, ideas, and tips from various teachers and presenters. All too often, we use flame and football shapes on flat surfaces, wasting composite by grossly overfilling (which takes additional time to remove), and scratching the seal out of the enamel margins. In short, we are still using instruments left over from the amalgam age.

One of the best hand instruments ever developed for restorative procedures is the 21B Acorn Burnisher (ADAI, Minneapolis MN); its design was based on the actual anatomical slopes and angles that are found in healthy posterior teeth.

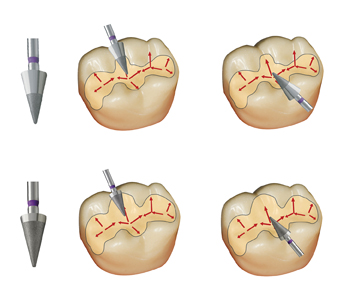

Now, imagine one hand instrument (Fig. 1) that can do the work of 4, including insertion and manipulation in the narrowest of conservative proximal boxes (0.8mm and 1.5 mm). Flip ends and you have a robust ball burnisher that creates a smooth marginal transition at the composite-enamel interface with minimal overfill (~10%). This saves composite and polishing time. Simply twirl the instrument to use the 97o Acorn Burnisher to develop primary anatomy prior to curing.

Fig. 1

The 4-in-1 Roetzer PPS (Posterior Packer and Sculptor, Power Dental Inc. Chicago IL) instrument creates the anatomy during placement. (Figs. 2 & 3) Thus, once the resin is cured, only minimal reduction is required. This is where the Occlusinator PRO (Strauss Diamonds Inc., Palm Coast FL) diamond finishing and polishing system takes over. (Fig. 4).

Fig 2

Fig. 3

and mesial pits as starting points for the acorn diamond burs.

Fig. 4

The Acorn Burs are available in 3 sizes, all incorporating the natural 970 angle (Fig. 4, left 3 red-band burs) to automatically refine the anatomy. Identifying the expected locations of the deepest pits, we select the most appropriately sized Acorn Bur to drop the anatomical definition. Once all the pits are prepared, we simply connect the dots – drop and drag. (Fig. 5) The two primary objectives and benefits of prescriptive finishing and polishing are the elimination of waste and consistency in performance.

Fig. 5

The patented Occlusinator Acorns are coated with 50µ particles. They also have a diamond-free zone around the periphery, preventing abrasive contact with the enamel; only the composite is polished and there is no nicking and scarring of the healthy tooth structures. (Fig. 6) The non-abrasive periphery also serves as a depth-cut limiter to prevent over-carving.

Fig. 6

Next, the Xmas Tree Occlusinators (blue-band burs), with 15µ diamond particles, are used for final adjustments. (Fig. 4) The Xmas Tree burs also have a diamond-free zone that allows polishing of the composite, not the enamel. One has a 50% diamond coverage zone, the other 80%. When used with water spray, these diamonds often preclude the need for any further polishing. (Fig. 7) The Xmas Tree diamonds are also indicated for polishing esthetic Class V restorations.

Fig. 7

The Occlusinator PRO System is a simple but comprehensive block of just 5 diamond burs that can save up to 50% of the chairside polishing time, simplify and expedite the restorative process, and virtually eliminate the inadvertent creation of enamel scratches that will serve as plaque-magnets. It is designed to work with the PPS Instrument, but both are available separately.

The Occlusinator PRO is a prescriptive polishing system, that has evolved from the popular RAPTOR System (American Diamond Instruments, Salt Lake City UT) of the 1990s. A prescriptive approach eliminates guesswork. The width of the isthmus and the number and locations of the occlusal pits determine the polishing bur size. (Fig. 8) All practitioners can benefit from a methodical, scientifically based, and sequential polishing system.

Fig. 8

Oral Health welcomes this original article.

About the Author

Dr. Pat Roetzer (Marquette University) completed a GPR and taught at the Veteran’s Administration while establishing his private group practice. He has developed successful restorative Systems including: Unicore Post and Drill, RAPTOR, NitroThermalite/Tescera, Damit!, and Fifth Hand Impression. Dr Roetzer is Director of Operative Dentistry, University of the Pacific/Dugoni School of Dentistry, and International Student Program Director.

Dr. Pat Roetzer (Marquette University) completed a GPR and taught at the Veteran’s Administration while establishing his private group practice. He has developed successful restorative Systems including: Unicore Post and Drill, RAPTOR, NitroThermalite/Tescera, Damit!, and Fifth Hand Impression. Dr Roetzer is Director of Operative Dentistry, University of the Pacific/Dugoni School of Dentistry, and International Student Program Director.

RELATED ARTICLE: Case Study: Begin With the End in Mind – From Wax to Composite